Phone: +49 6171 9758-0

Optical spectroscopy is one of the most versatile tools in modern process analytical technology. Samples to be analysed emit material-specific radiation after interaction with light, from which the chemical composition of the samples is determined. For solid materials, morphological parameters such as grain size or surface roughness can be determined as well.

Our dedicated industrial spectrometers provide high-speed analysis of ingredients and can be used for qualitative analysis such as variety identification as well as for the quantitative determination of intermediate and finished products directly in the process.

Advantages of spectroscopic methods:

Especially for process analytical applications in an industrial environment, the performance of optical spectroscopy is highly advantageous:

Both embedded and PC-based versions offer two alternative system approaches covering the state of the art in process-enabled industrial spectroscopy in the best possible way:

Dedicated to industrial applications, all our systems are designed to be low-maintenance and robust against harsh or aggressive environments.

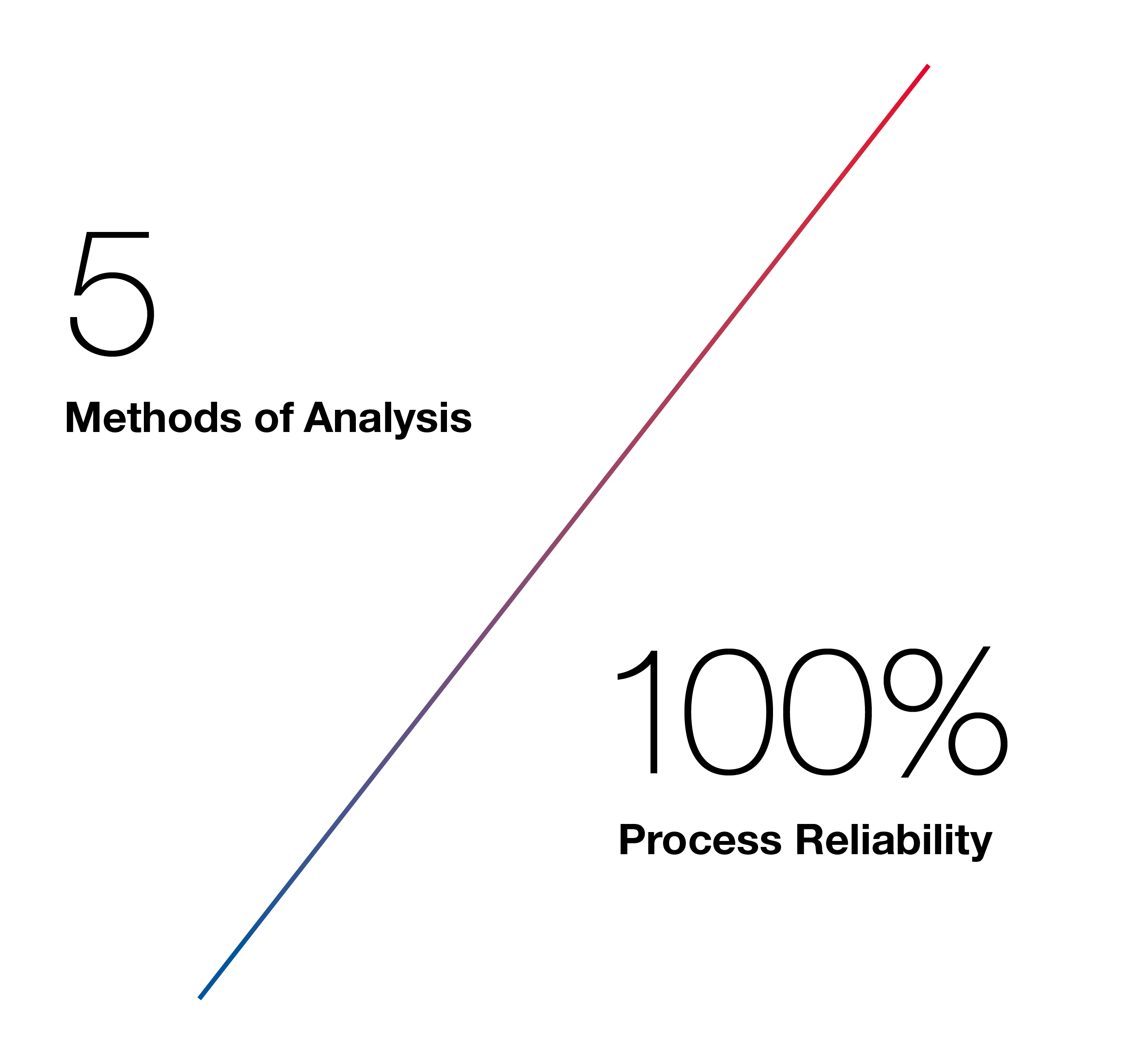

Depending on the application and the detailed requirement specifications, we provide the appropriate spectroscopic method:

Detection of electronic transitions

Spectra in the UV range with its easily assignable absorption lines offer a selective, molecule-specific detection of the substances under examination. Due to our low-scattered light and solarization-resistant systems, Deep UV applications are possible as well. In addition, the visible range provides highly resolved colour information.

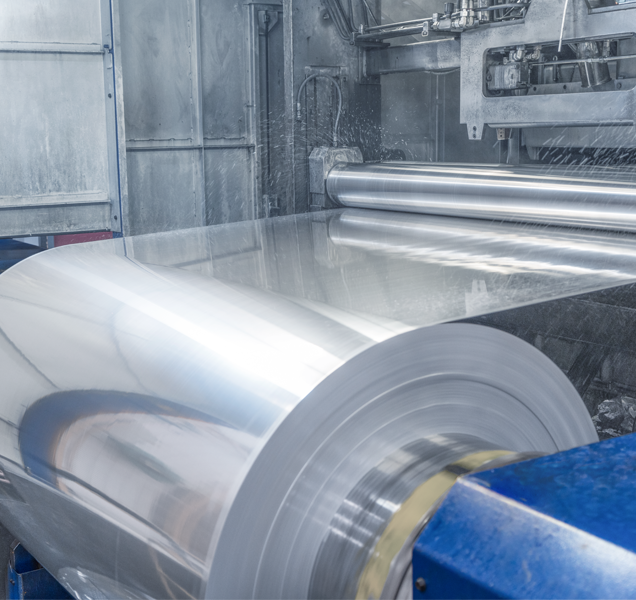

Vibrational spectroscopy (overtones and combinational bands)

Almost any organic substance exhibits distinct vibrational spectra, making NIR spectroscopy one of the most versatile and widely used methods in ingredient analysis, including the quantitative determination of chemical compositions as well as qualitative analysis such as variety identification. The NIR wavelength range is also suitable for coating thickness measurements in the ยตm range.

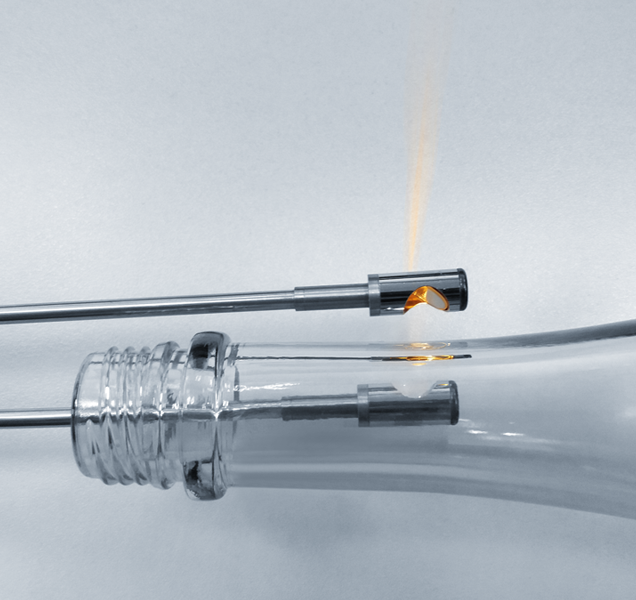

Inelastic scattering

Raman spectra, with their characteristic fingerprint signatures, allow a highly specific detection of a wide variety of molecules. Thus, substance-specific quantifications are also easily accessible due to significant peak characteristics. Raman spectroscopy is particularly suitable for measurements in aqueous solutions, as water itself does not show any predominant component in the spectrum.

Our team of application engineers would be pleased to support you in selecting the most suitable method for you.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information